X-ray Powder Diffraction (XRPD) is a versatile technique that can be used to identify any crystalline substances, such as most minerals.

It can also be used to quantify the proportions of different minerals or indeed many other substances when they are present in a mixture.

All of our routine XRPD methods, including our quantitative methods, are UKAS accredited. This means they have been thoroughly verified, audited and checked to ensure they are robust analytical methods that give reliable results.

Clay minerals and clay size fraction analysis

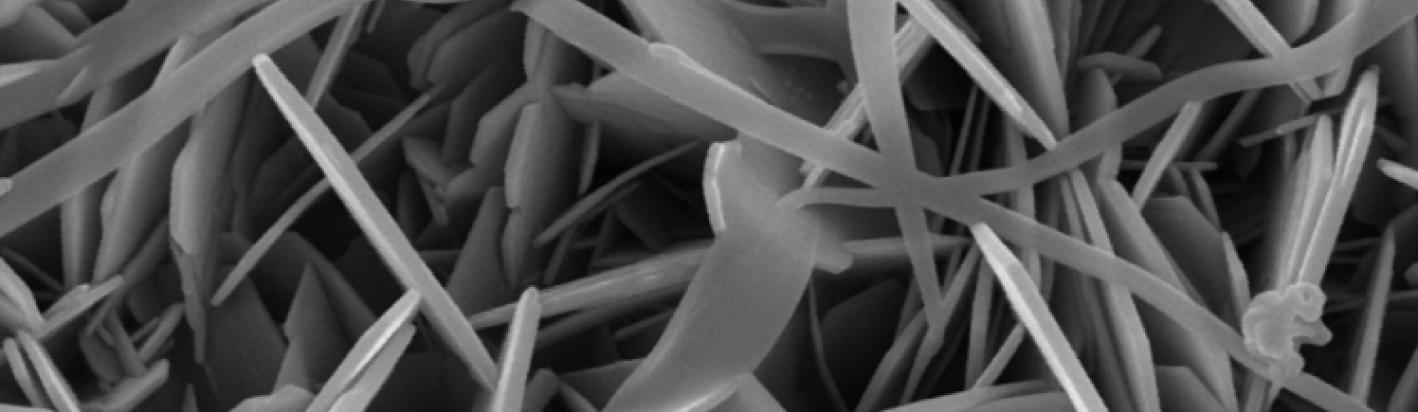

We specialise in the analysis of clay minerals by XRPD. Typically, clay mineral analysis involves the separation of a clay sized fraction (usually < 2 micron) from the sample. Once obtained the clay fraction is prepared by collecting it on a filter and transferring the layer of clay to a glass slide substrate. This so called 'filter peel' method enhances the preferred orientation of the platy clay particles which helps to obtain a good diffraction signal from the diagnostic basal planes of the clay minerals. It is also the best way to make a homogenous sample, essential is quantitative results are required. These oriented samples are run on the diffractometer (air-dried) and then run again following various treatments such as solvation with ethylene glycol, and heating to specified temperatures for specified times. Other treatments may be appropriate for the identification of some clay minerals. Peak positions, shapes and intensities and changes in these between treatments are diagnostic for the identification of different clay minerals. Following identification, quantitative analysis may be made by an intensity ratio method whereby the integrated intensity (peak area) of selected clay mineral peaks is related to their weight fraction in the mixture by means of a predetermined constant of proportionality termed mineral intensity factors (MIF) or more generally known as Reference Intensity Ratios (RIR). These are most readily determined from calculated one dimensional X-ray diffraction patterns, using for example the NEWMOD program as described in Moore and Reynolds (1997).

Precise identification of clay minerals is the first step in any clay mineral analysis, and we base our identifications on years of experience of the interpretation of diffraction patterns from clay minerals and their responses to various ancillary treatments.

Whole rock or bulk material analysis

Sample preparation is often the key to reliable quantitative XRPD work and a method known as Spray Drying has been further developed at The James Hutton Institute for use in the quantitative analysis of bulk materials by XRPD. The major advantage of spray drying is that XRPD data become highly reproducible. This is a result of the elimination of preferred orientation (texture). The reproducibility of the diffraction data that is obtained is at the heart of the accuracy of all our quantitative methods.

Our main methods of analysis, particularly for clay bearing materials are based on full pattern fitting methods that use measured diffraction patterns. This is because most clay minerals contain defects/disorder which cannot be readily modelled and so the approach of using patterns measured from real materials is often much more reliable and accurate.

In addition, when appropriate, we also use the Rietveld method, which can be applied to any materials for which crystal structure details are available.