Both the spherical shape of the granules and the way spheres pack together in a powder holder ensures random arrangement of the component particles. In addition, indeed as a consequence of eliminating preferred orientation, the XRPD patterns of spray dried samples are extremely reproducible as illustrated below.

Examples of spray dried materials

|  |

| Spray dried kaolinite. | Spray dried smectite. |

|  |

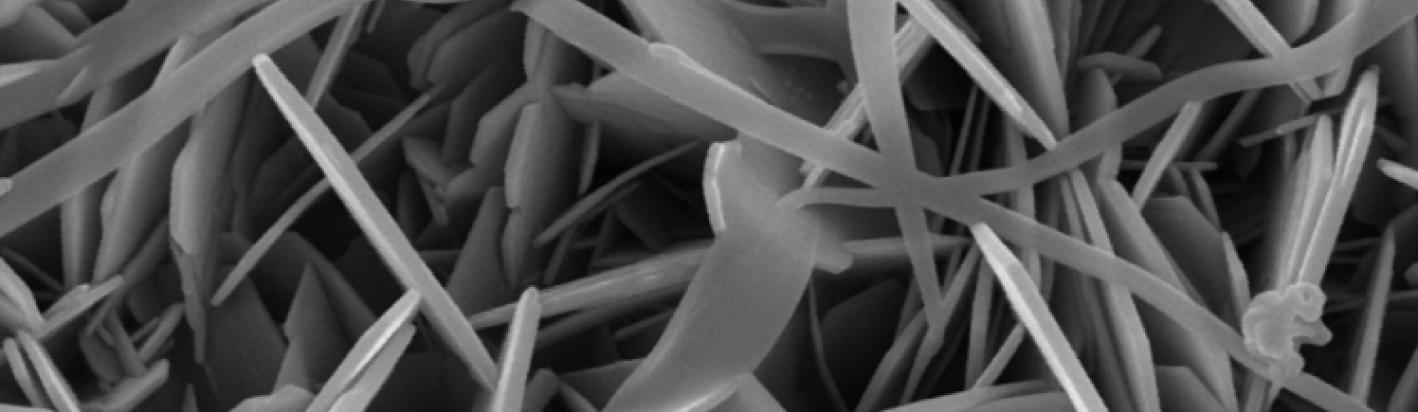

| Spray dried muscovite. | Spray dried talc, illustrating the effect of particles which are slightly too large. |

|  |

| Spray dried shale. | Spray dried quartz showing internal structure. Fines migrate to the outside during drying. |

|  |

| Backscattered electron image of section through granules (spray dried sandstone). | Backscattered electron image of section through granules (spray dried sandstone). |

Examples of spray dried and non spray dried powder x ray diffraction patterns.

XRPD patterns of a synthetic mixture of 25% chlorite, 25% muscovite, 25% albite and 25% calcite, all minerals which frequently exhibit preferred orientation. A) XRPD patterns from 18 separate loadings of a freeze-dried portion of the mixture by 3 different operators (red, green, blue, 6 patterns each). B) XRPD patterns from 18 different loadings of a spray-dried portion of the mixture by 3 different operators (red, green, blue, 6 patterns each).